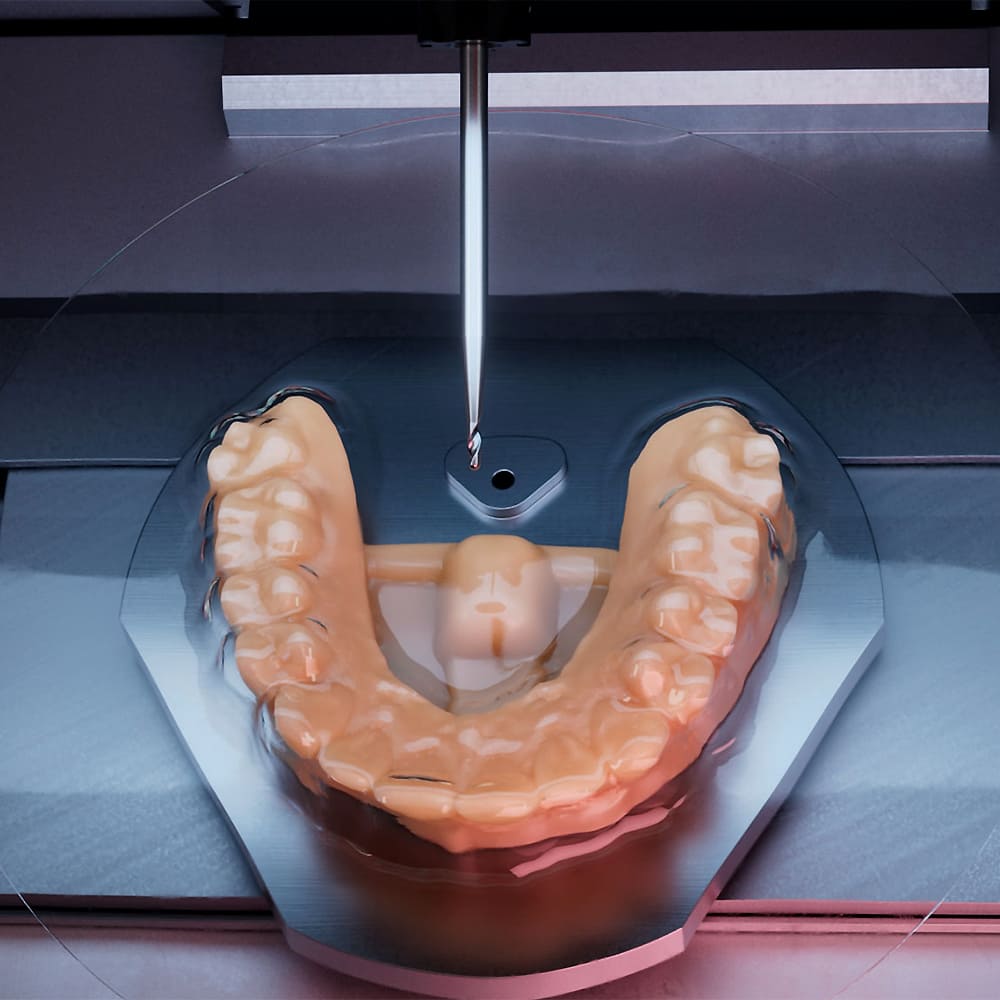

The Vhf E3 Dental Milling Machines – automate your workflow.

The Vhf E3 is simple to commission and operate, and fits seamlessly into your workflows. Our in-house developed TRIMCAM software automatically recognizes the trimline on which the occlusal appliance is milled out from the available planning data. So, you’ll get started right away.

Powerful 800 W 60,000 rpm spindle.

Quick and easy trimming of other occlusal appliances.

Full machining of aligners in under 60 seconds.

Maximum freedom of installation site as the machine requires no compressed air.

No tool change necessary with ONETOOL technology.

CAM software and easy operation with the integrated CAM software TRIMCAM, with no license fees.

True to the motto: unpack, connect, start milling!

Benefit from the machining of aligners in under 60 seconds. This saves you a lot of time compared to manual production – and on top of that you gain the high precision of CNC production.

The tool-free clamping system further simplifies your work processes. This quick workpiece change enables you to produce entire series of aligners quickly and easily.

With a machine weight of only 25 kg and no use of compressed air, the compact Vhf E3 offers maximum flexibility in terms of the installation site. Meticulous attention has been paid to the details: for example, no separate extraction system is required – thanks to the practical collection tray for chips.

100% developed and manufactured in Germany, the Vhf E3 impresses with its precise results and outstanding reliability – not only for aligners, but also for bite splints, grinding splints and other splints, including sports mouthguards. Despite its compact design, the interior of this machine contains only high-quality industrial components.

Vhf. Creating Perfection.

With 35 years of experience, vhf is a leading manufacturer of dental milling machines. As a CAM full-service provider, vhf meticulously develops and produces each individual milling machine and the perfectly matched tools and software all in-house. Everything from a single source. Made in Germany.

Technical Data Vhf E3 Dental Milling Machines

| Fields of application | Dry machining |

| Materials | Thermo-formed plastic foil |

| Indications | Aligners and other splints |

| Holder systems | Holder for tool-free clipping in of the aligners |

| Construction | Sturdy aluminum structure |

| Housing | White high-gloss lacquer finish · upward opening lift door to the workroom |

| Number of axes | 3+1 |

| Linear axes X-/Y-/Z-axis | X-axis: rack and pinion drive · Y-/Z-axis: trapezoidal screw spindles · motor resolution 10 μm · max. axial backlash 0.06 mm |

| Rotary axis B-axis | Rotation angle: 360°, infinite |

| Control unit | Control electronics with continuous path progression and dynamic pre-calculation · hardware-based real-time operating system with standardized instruction set · FPGA-integrated processor · updateable hardware · real-time path and ramp calculation via dedicated hardware engines in the FPGA · four-quadrant control of the motors for particularly smooth running · multiple digital I/Os for controlling the peripherals · integrated inverter for synchronous and asynchronous motors, electronic gate detection · Ethernet and USB interface |

| Lighting | RGB LED lighting with status indication |

| General | High-frequency spindle with mechanical tool change |

| Speed | Up to 60,000 RPM |

| Power | Peak power (Pmax): 800 watts · continuous power (S1): 450 watts |

| Bearing | 2-fold hybrid ceramic ball bearing |

| Collet | Collet type ER8 for tools with 3 mm shank diameter |

| Dry | Compressed air-free operation without suction |

| Power supply | 100–240 volts · 50/60 Hz, 320 watts |

| Data | 10/100/1000 MBit/s BaseT port (auto-sensing) Ethernet via RJ-45 socket |

| Operating temperature | Between 10 °C and 35 °C |

| Air moisture | max. 80 % (relative), non-condensing |

| All models | CE |

| North America model | UL 61010-1, CAN/CSA C22.2 No. 61010-1 |

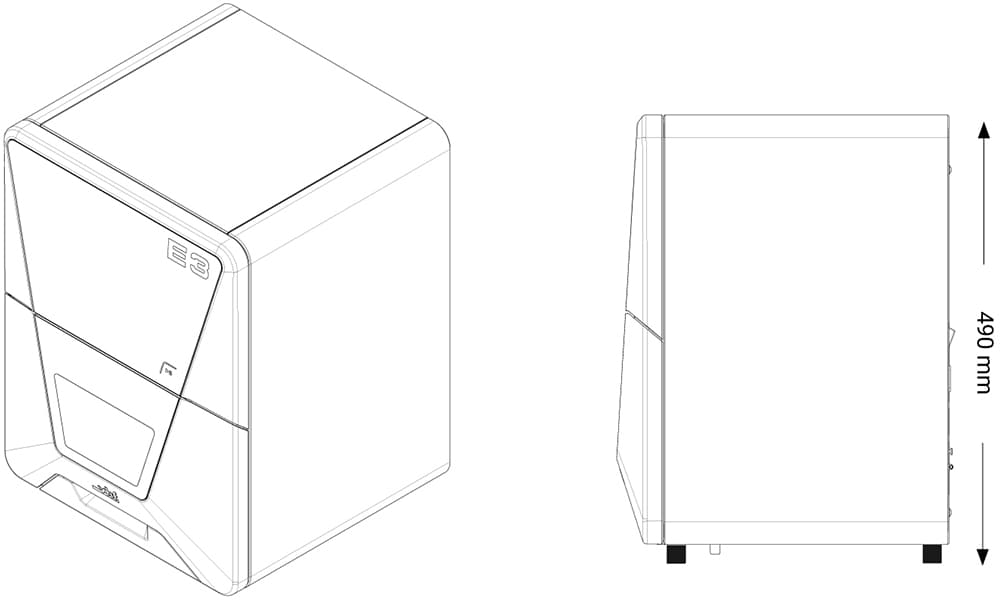

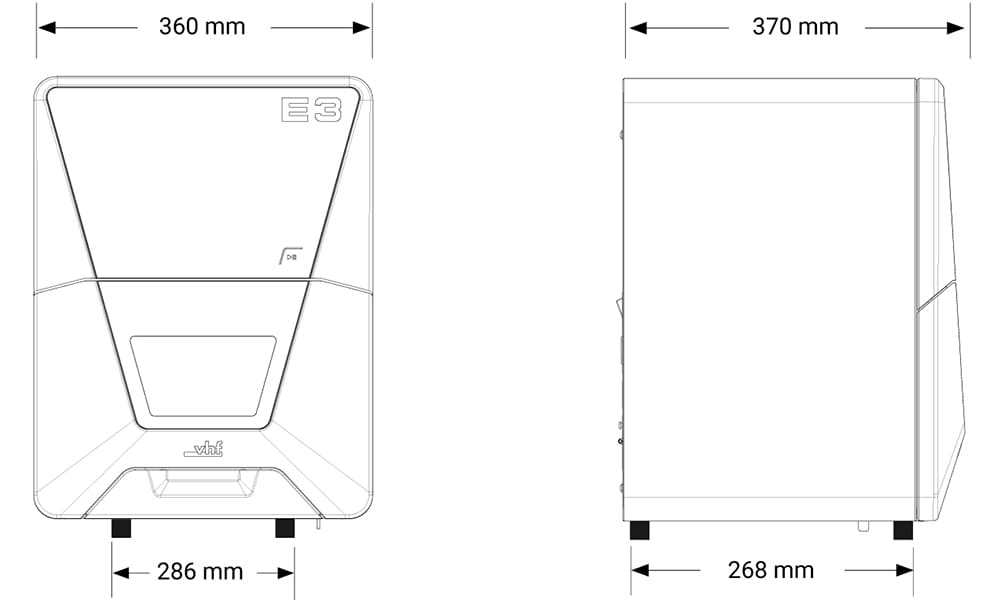

| Dimensions (W/D/H) | 360 × 370 × 490 mm with closed door · 360 × 420 × 490 mm with open door |

| Footprint (W/D) | 286 × 268 mm |

| Weight | 25 kg |

| CAM Software | TRIMCAM software for aligner production included in the scope of delivery |

| Accessories | Calibration set incl. stirrup measuring screw · Torx driver · torque driver 1.5 Nm · cleaning brush · cleaning scrubber and microfiber cloth · radius cutter (2 pcs.) · clamping wrench · open-end wrench · power cable · Ethernet network cable |