The 4-axis milling machine for blocks and abutments for laboratory and practice

The Vhf N4+ is ideal for in-office laboratories that want to produce the work without delay and avoid the higher costs associated with external production. With the combination of the wet grinding machine Vhf N4+ and a dry milling machine, users can work simultaneously and minimize the cleaning effort that most hybrid machines would require.

The Vhf N4+ is a wet processing machine for grinding glass ceramic, composite and zirconia blocks as well as titanium abutments. This machine combines the high precision and fast drives common to all vhf machines with a liquid cooling system in an extremely compact housing.

Maximum freedom of indication:

Crown | Bridge

Inlay | Onlay

Abutment

Veneer

Features and Benefits Vhf N4+ Dental Milling Machines

Exceptional precision

- Restorations in Ultra HD

- Premium spindle with four-fold ball bearing made of hybrid ceramic for the highest concentricity

- 3 µm repetition accuracy

Sophisticated design

- Spindle with water cooling for perfect results, even in continuous operation

- Eight liquid nozzles for steady tool cooling

- Highest rotational speeds of up to 80,000 rpm with 800 watts of power

- Heavy industrial quality

Absolute independence

- Around 40 block materials from a great variety of manufacturers – with upward tendency

- > 1,300 implant platform for titanium and CoCr prefab abutments from different manufacturers

- Ideal for labs and in-office labs

Outstanding reliability

- 100% developed and manufactured in Germany

- 24 months warranty

Highly economical

- PUREWATER: no grinding additives necessary, except for titanium processing

- Work on up to 3 blocks with 45 mm length at the same time

- Milling of screw channels – saves costs for meso blocks

- Conveniently removable cooling liquid tank

- Automatic changer for 8 tools

- Webcam in working chamber for remote monitoring and service

- Ethernet interface for stable connection

- Very easy operation via DENTALCAM software with DIRECTMILLFunction – included in scope of delivery and without license fees

Machinable materials:

Composites

Plastics | Wax

Glass ceramics

Zirconia

Titanium

CoCr

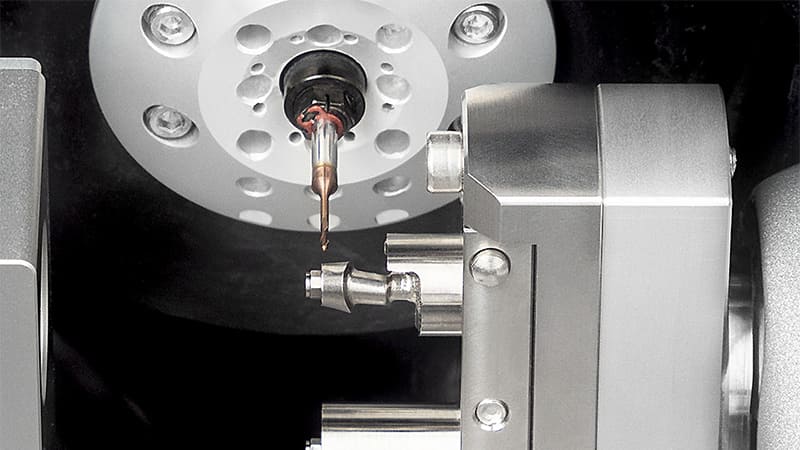

The essence of wet grinding

The N4+ is an efficient wet processing machine for grinding and milling glass ceramic, composite, and zircon blocks, as well as CoCr and titanium abutments. It impresses not only thanks to its high precision and fast drives, but also thanks to its ultra-compact housing with closed fluid circuit. Eight fine nozzles on the spindle direct the cooling liquid precisely onto the effective area between the tools and workpiece, delivering an optimal cooling effect.

Tool changes in a flash

The tool magazine can be inserted quickly and effortlessly in just one step. The automatic changer offers space for up to eight tools. The three compartment block holder is another highlight. That makes the N4+ the ideal partner for research and practice laboratories.

Outstanding precision

Scientists at the University of Washington confirmed an outstanding precision of −10 μm to +26 μm during demanding applications like milling titanium abutments.

Closed fluid circuit

The large fluid tank can easily be removed from the drawer.

For a variety of indications

For crowns and bridges, inlays, onlays, abutments, veneers, table tops, etc.

Technical Specifications Vhf N4+ Dental Milling Machines

| Fields of application | Wet machining |

| Materials | Glass ceramics, titanium, zirconia, composites, plastic materials – Blocks up to 45 × 20 × 20 mm |

| Indications | Crowns, bridges, fully anatomical crowns and bridges, inlays, onlays, abutments, veneers, table tops |

| Construction | Machine bed made of solid cast aluminum body |

| Housing | Sheet steel housing, white high-gloss lacquer finish, with working chamber flap and cooling liquid tank integrated in the drawer |

| Number of axes | 4 |

| Linear axes X-/Y-/Z-axis | Precision ball screws, rolled version · motors with resolution < 1 μm · ground precision guides made of steel · repetition accuracy ± 0.003 mm |

| Rotary axis A-axis | Rotary axis with high run-out accuracy · rotation angle: 200° |

| Control unit | 4-axis simultaneous control electronics with continuous path progression and dynamic pre-calculation · hardware-based real-time operating system with standardized command set · FPGA-integrated processor · updateable hardware · real-time path calculation via dedicated hardware engines in the FPGA · four-quadrant control of the motors for particularly smooth running · multiple analogue and digital I/Os for controlling the peripherals · integrated inverter for synchronous and asynchronous motors, electronic gate detection · Ethernet and USB interface |

| Lighting | RGB LED lighting with status display |

| Camera system | Integrated in the working chamber for easy remote support and possibility of internal recording |

| General | High-frequency spindle, synchronous, with pneumatic tool clamping · sealing air to prevent debris from entering · automatic cone cleaning |

| Speed | Up to 80,000 rpm |

| Power | Peak power (Pmax): 800 watts · nominal power (S6): 600 watts · continuous power (S1): 440 watts |

| Bearing | 4-fold hybrid ceramic ball bearing · concentricity deviation at inner cone < 3 μm |

| Collet | Stainless steel collet with ceramic coating for tools with 3 mm shank diameter and max. 35 mm total length |

| Tool change | Tool magazine for 8 tools, removable · length measurement and tool breakage monitoring via precision measuring key · access through working chamber door, safety lock |

| Wet | Multiple fluid nozzles on the spindle · integrated cooling liquid tank (3.5 litres) with active carbon filter system · flow-sensor for monitoring the liquid supply · PURE |

| Compressed air | 4 bar: 25 l/min up to 8 bar: 45 l/min · air purity according to ISO 8573-1:2010 |

| Power | 100 · 240 volts · 50/60 Hz, 640 watts |

| Data | 10/100/1000 Mbit/s BaseT port (auto-sensing) Ethernet via RJ-45 socket |

| Operating temperature | Between 10 °C and 35 °C |

| Air moisture | Max. 80 % (relative), non-condensing |

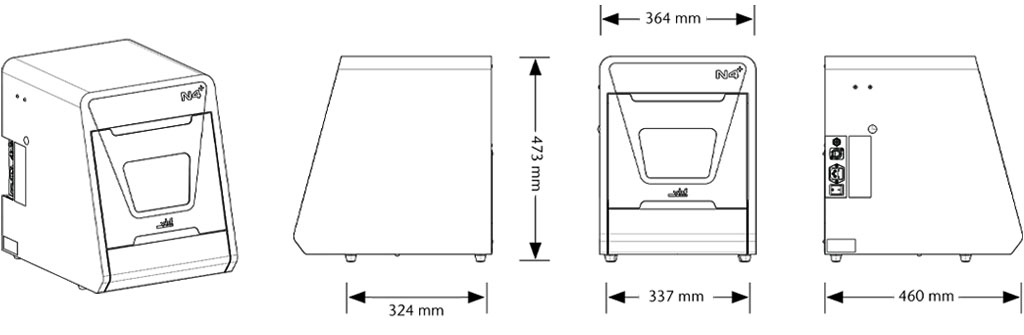

| Dimensions (W/D/H) | 364 × 460 × 473 mm · 364 × 667 × 473 mm with open flap and drawer |

| Footprint (W/D) | 337 × 324 mm |

| Weight | 52 kg |